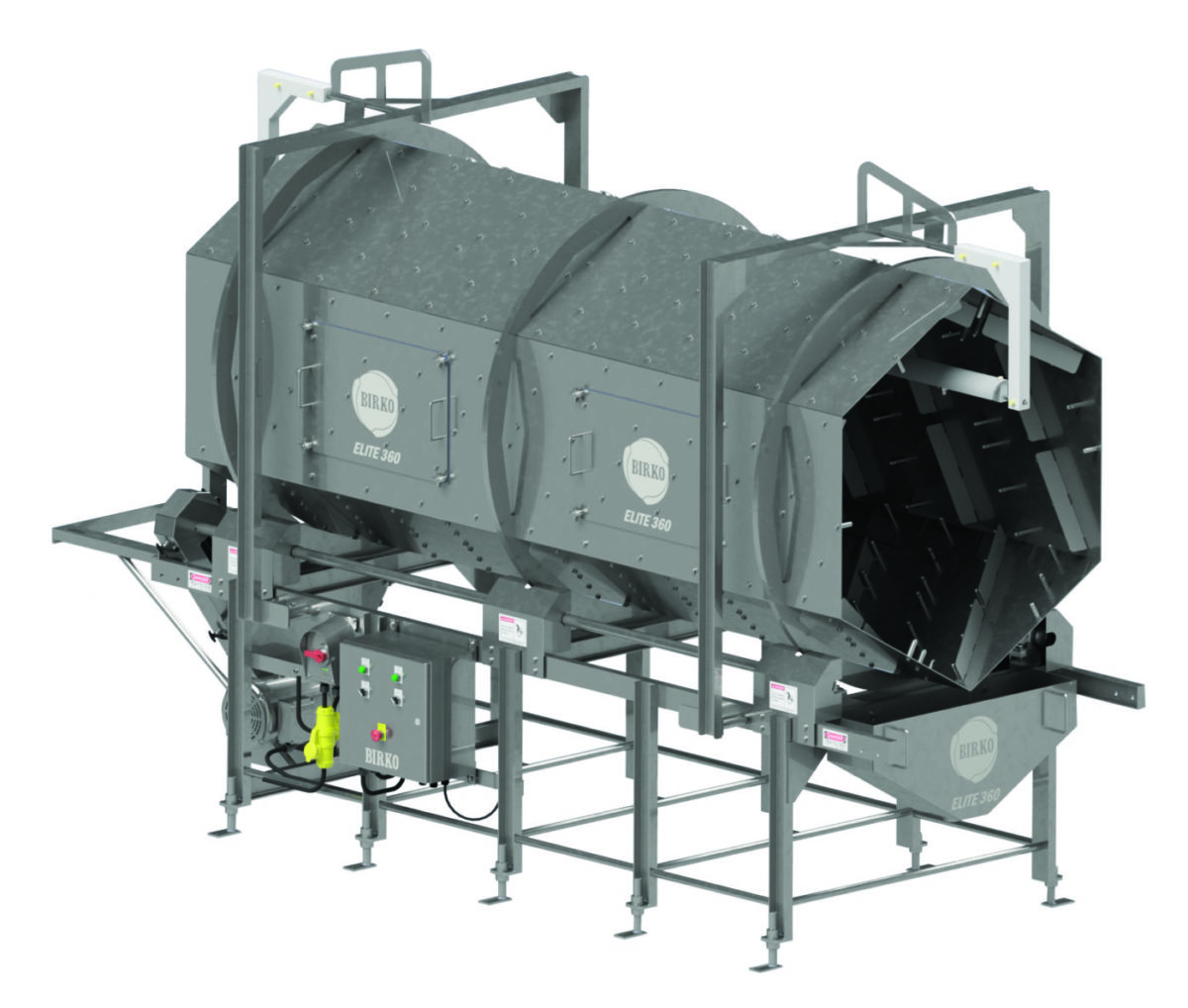

Interventions. Decontamination. Antimicrobial interventions. Intervention application. Precision application. No matter what you call it, it is a crucial step for any food manufacturer. And we’ve created a way to make this process more effective, efficient and cost-effective: Elite 360® precision application technology™.

Elite 360® is a groundbreaking new electrostatic intervention technology that has the potential to significantly improve the safety of today’s food.

The use of electrostatic in the protein industry isn’t new, but our ability to harness this technology in an application that solves significant food safety issues is new.

The Elite 360® technology has the potential to disrupt how antimicrobials are applied to protein products, specifically parts and trim prior to grind.

How does Elite 360® work?

An antimicrobial intervention (like PAA) is applied electrostatically to cover the product, using the least amount of antimicrobial possible, while being as effective as possible. The technology not only reduces pathogens, but it will reduce the amount of chemicals that a plant applies/wastes and significantly reduces water use as well as wastewater treatment costs.

Elite 360® offers the same efficacy as dip tank applications, but uses 95% less water and chemical.

Testing the Elite 360® Technology

Birko is partnering with AB Foods, American Foods Group, Central Valley Meats and Colorado State University to test our patented technology and bring the concept to commercialization. The result has been an extremely collaborative and transparent approach to testing. Together we’ve been able to overcome many of the obstacles previously encountered with the use of electrostatics.

After years of work in the Colorado State University Center for Meat Quality & Safety, we were able to fine tune the precision application technology and address challenges that can accompany electrostatic (employee safety being one of them). Earlier this year we launched our first test in a commercial setting at AB Foods in Toppinish, Washington.

We tested Elite 360’s ability to handle a capacity of 250-750 lbs/minute and up to 7120 approved levels of PAA (up to 1800ppm PAA). The line we selected was a 50/50 trim line running 285lbs/minute. We used a top end of 1800ppm PAA and had exposure times of 20 seconds. The results were impressive to say the least: a 1.7 log reduction of e.Coli with essentially zero wasted solution, and full coverage. We’ve seen similar results on Salmonella in poultry with both skin-on and skinless product.

| Phase 1 – Dye Test Before Elite 360 |

Phase 1 – Dye Test After Elite 360 |

|---|---|

|

|

What’s Next for Elite 360®

Additional testing is underway to repeat these results, optimize the electrostatic operating parameters and improve results even further before commercializing Elite 360® for red meat.

The potential for Elite 360® technology is endless, in fact, Elite 360® systems for poultry and produce, and other precision application technologies, are also in development. In the meantime, feel free to contact me at [email protected] with any questions about this groundbreaking new technology or subscribe to our Elite 360 mailing list.

Additional Resources:

- It’s Not a Silver Bullet to Your Challenges, But It’s close, Birko Blog

- New Intervention Technology Met With Excitement at NAMI Conference, Birko Blog

- The Age of the Algorithm, Meatingplace

Mark Swanson, CEO, Birko, can be reached at [email protected] or (303) 289-1090.

Mark Swanson, CEO, Birko, can be reached at [email protected] or (303) 289-1090.