Cooking oils. Pet food. Cosmetics. Fertilizer. Biofuels. Lubricants or raw materials for soap and surfactant manufacture. Whether part of the food chain or as a component in industrial or household items, there’s no shortage of end uses for animal by-products. Rendering operations make all this and more possible by processing animal-derived waste materials from harvest and further processing facilities into valuable products that allow the waste materials to be repurposed. That means rendering operations play an important role in the food processing industry and our larger economy, as well as the sustainability of the food industry.

But that role can carry several complex challenges. Rendering facilities and departments must juggle not only the rendering process itself but also odor control, product quality, and sanitation.

Birko offers several product groups that help address these challenges and help rendering facilities produce quality products and navigate USDA regulations.

At its most basic, the rendering process involves heating or cooking the ground-up waste materials to melt or render the fat away from the protein and bone. The resulting mixture is then centrifuged to separate the fat, generally called tallow, from the water and other solids, which are then dried.

Custom Solutions and Rendering Expertise

Antifoams for Rendering Cookers

The cooking process generates foam which can reduce process efficiency. Birko provides several anti-foaming products that can effectively control foam.

Birko anti-foam products:

- Birko D-Foam – an easy to use wax solidified unit dosing product

- AF 100 – silicone-based liquid anti-foam

- AF 30 – silicone-based liquid anti-foam

- AF 10 – silicone-based liquid anti-foam

Download safety data sheets for Birko anti-foam products.

Tallow Refining Products

The higher the USDA grade of the rendered tallow, the greater its value to the producer. The grade is designation is reliant on the free fatty acid content and color of the tallow. We offer several tallow refining aids to help neutralize free fatty acids prior to entry of a product into the centrifuge. These products help rendering facilities add value to their products and reach additional markets.

Tallow refining aids include:

- Genzolate

- Genzolate Aid 3

- Top White

In addition to tallow refining aids, Birko supplies reagents and procedures to allow rendering facilities to test the free fatty acid content of their tallow, including:

- Indicator Alcohol

- 25N NaOH

Download safety data sheets for Birko tallow refining products.

Acids for Edible and Inedible Rendering

The separation of tallow from the aqueous phase under centrifugation is enhanced by optimizing the pH of the mixture. Birko provides a range of several acid products to adjust the pH in both edible and inedible tallow processes:

- Phosphoric Acid FG

- Phosphoric Acid Tech

- Rend-R-Aid Tech

- Rend-R-Aid FG

Download safety data sheets for rendering acids

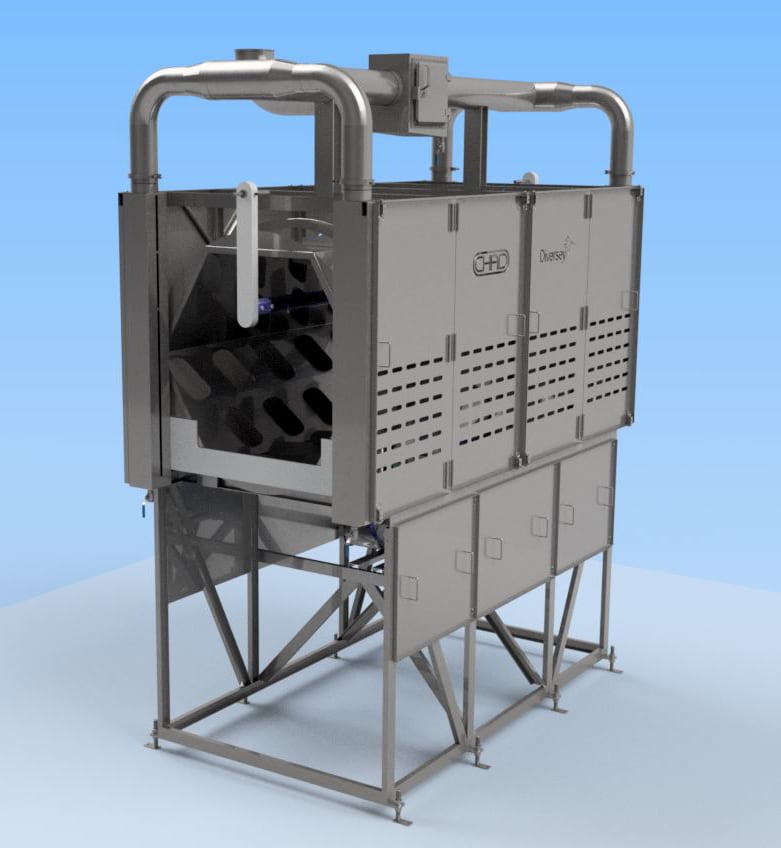

Odor Control Systems for Rendering Facilities

A major challenge for rendering facilities is odor control of exhaust air from blood and solids dryers. Chlorine dioxide is one of the most effective chemistries for use in rendering facility exhaust air scrubbers. Birko can source chlorine dioxide generation systems and provides the three-part chemistry used to generate chlorine dioxide:

- De-Scent

- 10-Chlor

- 25% Hydrochloric Acid

Contact us for more information on odor control systems for rendering facilities.

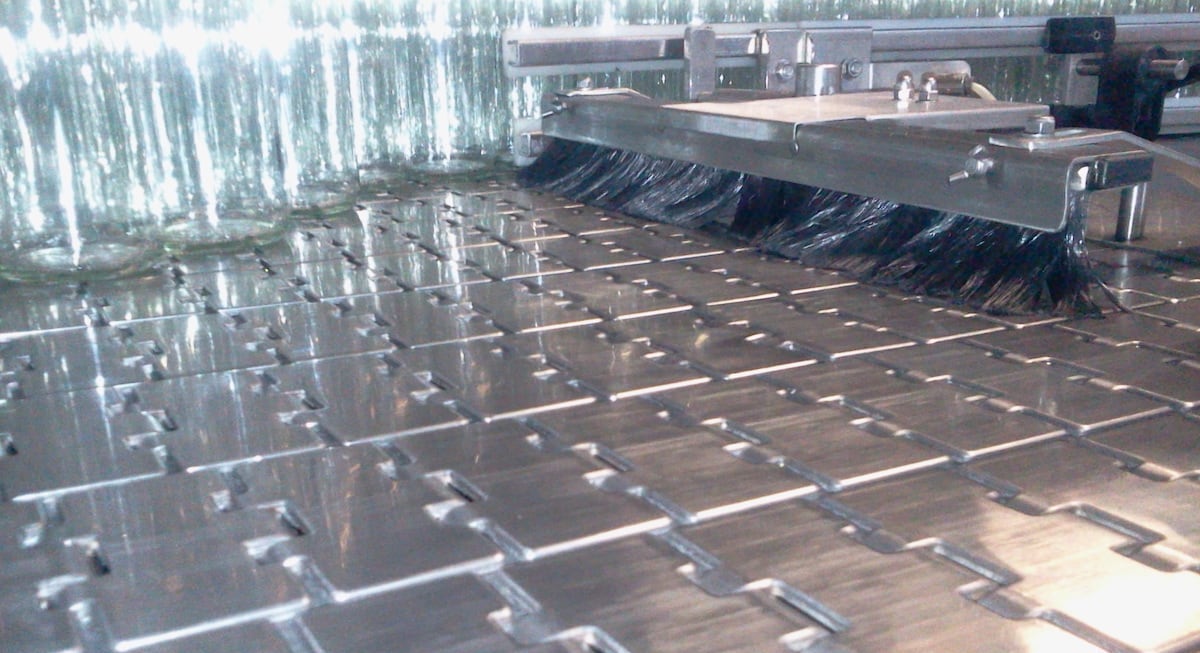

Cleaning and Sanitation for Rendering Facilities

Although some rendering facilities do not produce food-grade products, effective sanitation is still imperative for quality control and preventing the spread of pathogens and viruses. Birko’s products, Liquik 250 and Shine A Line are industry go-to products for rendering department sanitation. Liquik® 250 is a strong blend of caustic, detergents, and chelating agents and is appropriate for use as a heavy-duty soak tank and CIP cleaner. Liquik® 250 features outstanding cleaning performance on fatty, greasy, and other organic soils and is the preferred CIP cleaner for rendering facilities.

Birko’s Shine A Line acid CIP, cleans and enhances the appearance of rendering equipment by leaving a shine after usage.

Birko rendering cleaning and sanitation products:

- Liquik® 250

- Shine A Line

- Ultra-Quat

Download safety data sheets for Birko sanitizers.

Denaturants for Meat and Poultry Products and Carcasses

USDA regulations require that all meat and poultry carcasses and parts are intended for disposal or purposes other than human food. Must be clearly and indelibly marked before transport to an off-site rendering facility. Birko denaturants and de-characterizers are non-toxic and do not affect meat, bone meal, or by-products used for animal feeds and pet food. We provide a range of products in various colors to fit the needs of the individual processing facility.

Birko’s denaturants include:

- Denaturant G

- 4-D Denaturant

- Denaturant Black

- Liquik Char

- FD&C Red Concentrate

- FD&C Blue Concentrate

Download safety data sheets for Birko denaturants.

Birko prides itself on combining food safety, sanitation, and chemistry expertise with decades of experience in providing integrated food safety solutions to food processors across industries. At Birko, we work as your partner in food safety to ensure product quality, pathogen prevention, reduced risk, and a strong bottom line.

Contact us today to learn more about our solutions for rendering facilities and departments, and follow our blog for more insights.