October 13, 2023

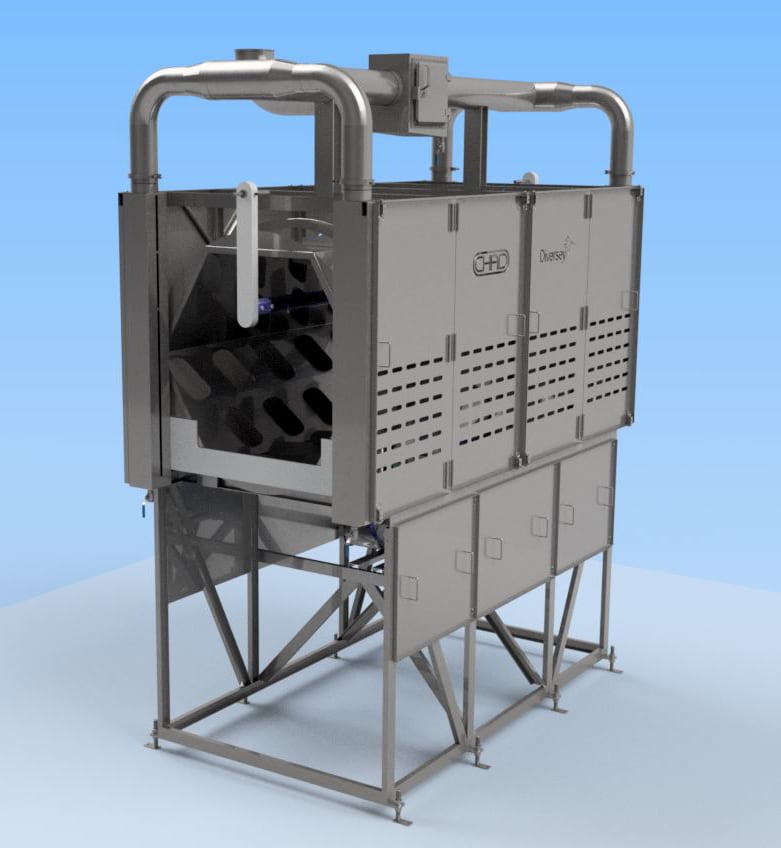

Efficiency Meets Sustainability: The Impact of Diverclean Sonic on Meat and Poultry Processing Facilities

Meat and poultry processing is not for the faint of heart. It involves heavy machinery, demanding cleaning routines, and a constant battle against tough soils like fat, protein, and tallow. Despite how crucial open plant cleaning (OPC) procedures are for maintaining proper hygiene and uncompromised food safety, they are often…