If you were unable to attend this year’s United Fresh Expo, you missed some great opportunities to network, learn about trends, hear from experts and discover innovations for fresh cut and produce processing.

Birko had the privilege of sponsoring the Food Safety & Technology meeting at the 2018 event in Chicago. Dr. Elis Owens and I also attended the meeting, and there are a few interesting and important takeaways we wanted to pass along to you.

1. FDA Says Get Ready for FSMA Inspections

Perhaps the most important piece of news came from a representative of the Food and Drug Administration who addressed the group. The FDA says official FSMA inspections will begin in earnest during spring of 2019.

That means produce and fresh cut processors have limited time to make sure they are following regulations outlined in the Food Safety Modernization Act. This sweeping piece of legislation is having a major impact on the produce industry.

All the details may seem tough to navigate, but it gets easier when you work with partners who are also food safety experts. Among FSMA’s requirements are the needs to have a documented food safety plan and appoint an official Preventive Controls Qualified Individual (PCQI) who has been trained in FSMA rules and regulations. The PCQI can be an employee, or that person could come from a third-party partner, such as Birko. We also help food manufacturers establish documented food safety plans.

Check out our blog post on food safety inspections and audits to learn more about what you can expect.

2. Formation of a Hygienic Design Committee

Members of the Food Safety & Technology Council announced plans to form a new committee focused on improving hygienic design in fresh cut and produce processing facilities.

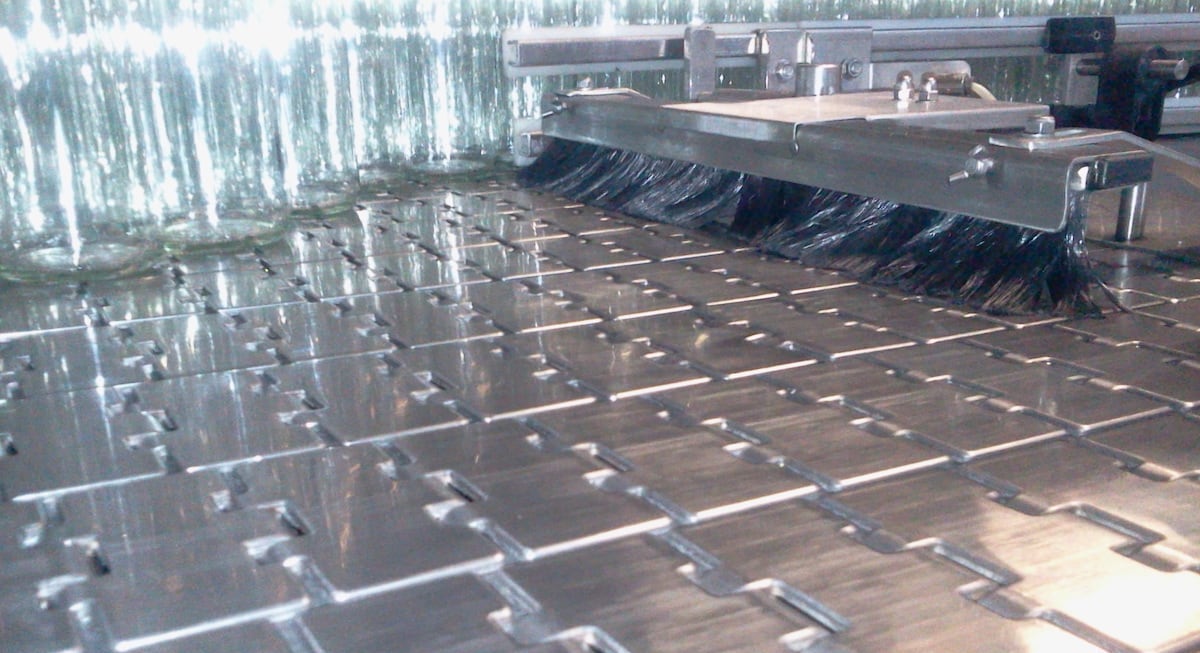

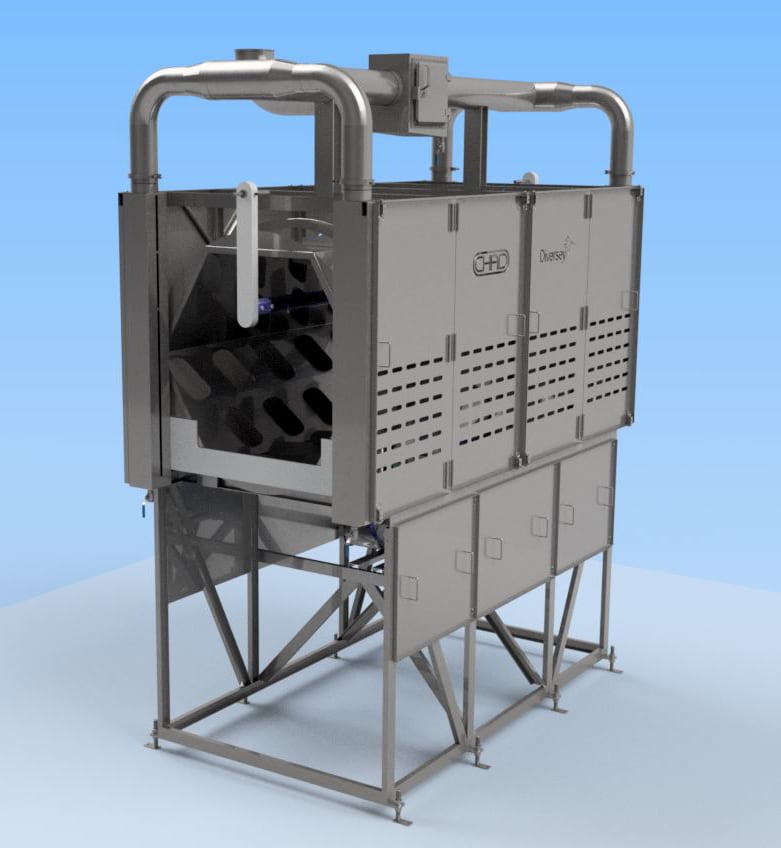

Also called sanitary design, this practice looks at plant layout as well as the equipment and materials used in food processing to determine whether food safety recommendations are being followed and sanitary conditions are maintained.

The new committee will specifically be considering ways to improve the design of food processing equipment in the produce industry so that food safety risks are mitigated. This often involves finding ways to eliminate harborage areas (niches) where pathogens hide.

The protein processing industry has already developed a set of principles for hygienic design that also applies to produce processing. Dr. Elis Owens explains these foundational ideas in our article Sanitary Design 101 | 10 Principles Produce Processors Should Know in the Age of FSMA.

3. Sanitary Transportation Standards

Another food safety development shared during United Fresh came from the Supply Chain and Logistics Council. Members announced they are working on establishing protocols for sanitation in food transportation, including how to clean semi-trailers, refrigeration containers and shipping equipment. This is to help both shippers and carriers comply with FSMA’s Sanitary Transportation of Human and Animal Food rule.

Unless specifically outlined in a contract, the shipper is ultimately responsible for food safety throughout this portion of the supply chain. That means produce processors need to educate and instruct their carrier networks on how to transport food in sanitary conditions.

Since FSMA does not give clear instructions on how to meet these demands, general guidelines from the United Fresh Supply Chain and Logistics Council should be quite helpful. Anyone shipping applicable food needs to develop written procedures for carriers that:

- Ensure sanitary conditions of vehicles and equipment

- Ensure previous cargo does not make food transported in bulk unsafe

- Ensure food is transported under adequate temperature control

You can find an explanation of the Sanitary Transportation rule and learn more about how FSMA impacts shippers and carriers on the Birko blog.

From new technology to new regulations, events like the United Fresh Expo help food companies stay on the cutting edge and find groundbreaking solutions to challenges in produce and fresh cut. We highly encourage our customers to consider attending the 2019 event, June 10-12 in Chicago.

However, you don’t have to wait for the expo to gain insights into topics such as food safety and sanitation automation. The experts at Birko are ready to talk to you about best practices, sanitation products and innovative equipment that helps you become more efficient while protecting your brand’s reputation.

Check out our solutions for fresh cut and produce or contact Birko and find your local Technical Sales Representative today.

Miles Murphy, Business Development Director for Birko, can be reached at [email protected] or (720) 305-7812.

Miles Murphy, Business Development Director for Birko, can be reached at [email protected] or (720) 305-7812.