A recent blog from Bill Marler delivers an important message: that when it comes to microbiological food safety, pathogens don’t discriminate between organic and non-organic food. Accordingly, it is incumbent on all food producers to understand the pathogen hazards associated with their raw materials and their process and to take appropriate steps to produce a safe product. This includes the use of interventions where appropriate and proper sanitation products and procedures.

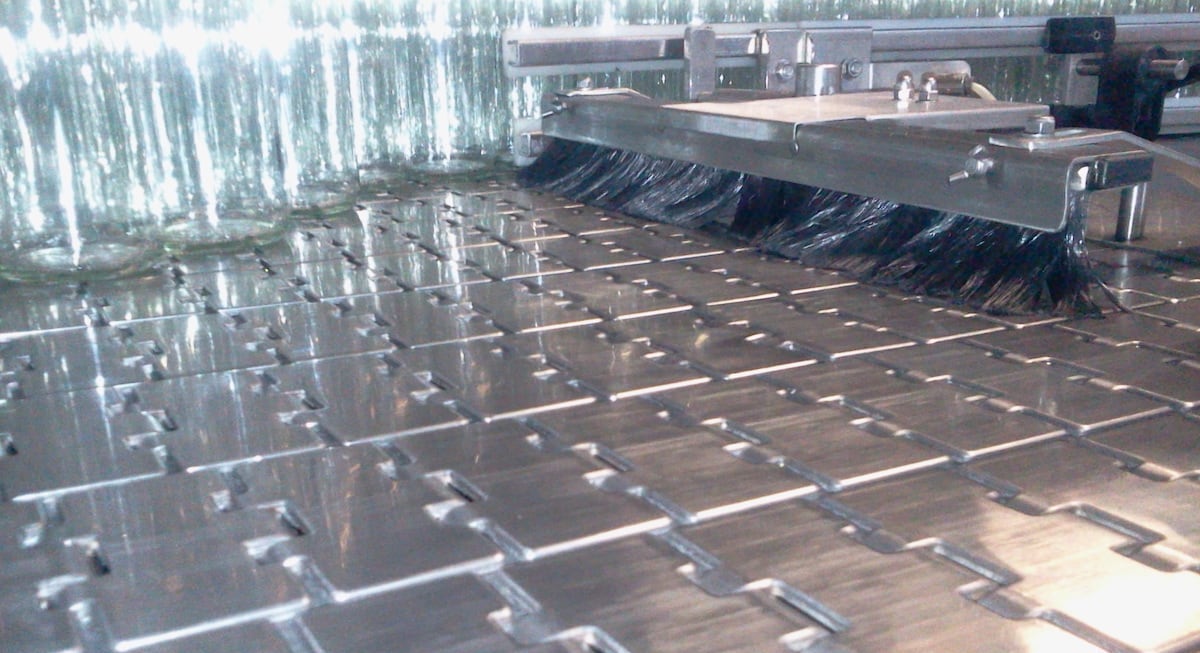

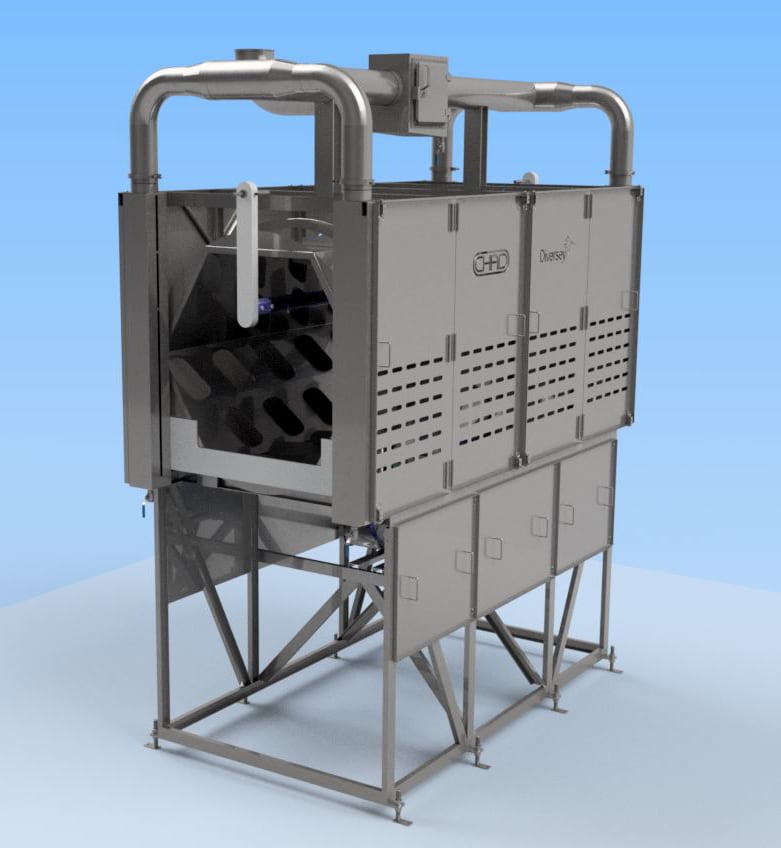

Cleaning and sanitation of an organic food production facility is really no different from cleaning and sanitizing a non-organic food plant except that only sanitizers suitable for use in organic facilities can be used. As in any food processing environment all product and packaging materials should removed from the environment before any cleaning starts. Cleaning products should be chosen based on the surfaces being cleaned and the types of soil present, and should be followed by a thorough rinse with potable water to remove all chemical residues. Testing the pH of the rinse water as it drains from the surfaces can be an effective indicator that cleaners have been adequately rinsed away. Cleaning must always be followed by application of a suitable no-rinse sanitizer.

The National Organic Program (NOP) List of Allowed and Prohibited Substances lists four types of chemicals as being suitable for use as no rinse sanitizers: sodium chlorite solution (acidified with citric acid); chlorine materials, including calcium hypochlorite, chlorine dioxide and sodium hypochlorite; ozone; and peroxyacetic acid. Quats or Quaternary ammonium sanitizers are not allowed. Birko’s BIRK-OX™, Bi-Chlor-ite and 10-Chlor™ are all acceptable under these regulations.

As with sanitizers, when it comes to antimicrobial interventions intended for direct application to food, organic processors have a much more limited range of choices. Lactic and citric acids (produced by microbial fermentation) and acid blends such as Birko’s Beefxide®, Lambxide™, Porkxide™, Chicxide® and Veggiexide™; Sodium Chlorite solution (acidified with citric acid) and peroxyacetic acid products such as Birkoside MP-2™ are the only interventions suitable for use on organic products. Producers seeking a 100% organic certification are limited to using organic apple cider vinegar.

No matter what you’re producing, animal protein, or fruits and vegetables, organic or non-organic, you owe it to yourself, your brand and your consumers to ensure that you are delivering a pathogen free food.

Elis Owens, Ph.D., Director, Technical Services, Birko, can be reached at [email protected], 303-289-1090.

Elis Owens, Ph.D., Director, Technical Services, Birko, can be reached at [email protected], 303-289-1090.