Meat & Protein Harvest

Equipment

Saving meat processing plants energy and water.

Protein processing plants have a tough task. Save money, time, water and energy while providing a consistently safe product. That’s where Birko comes in… providing innovative equipment that helps you save valuable resources while ensuring the highest level of food safety.

Hot water washing and pasteurizing equipment for meat harvesting and processing operations, antimicrobial mixing systems and spraying conveyors and automated chemical dispensing systems for greater control over plant sanitation. All protected by preventive maintenance programs, food-safe chemistry, service that is second to none, and an understanding of your challenges gained from decades in the business. That’s the Birko Advantage.

Meat & Protein Harvest Equipment

Harvesting/Processing Facility Equipment

Beef

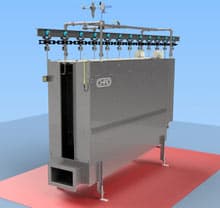

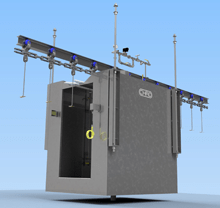

Hot Water Pre-Evisceration Carcass Wash

Description:

- The first intervention immediately after hide removal

- System is custom-built to fit your plant’s production rates and floor space

- Applying hot water to the carcass surface immediately after hide removal is one of the most critical food safety interventions on the harvest floor

- Kills pathogens before they have a chance to attach to and embed in the carcass surface

- Loose tissue and hair is washed off the carcass surface, resulting in less trimming required prior to final inspection

Tripe Wash Assembly

Description:

- Immediately after opening and dumping, wash the tripe to remove loose material and save water and chemical in the downstream washing and refining processes

- Can be floor mounted or suspended from an overhead structure

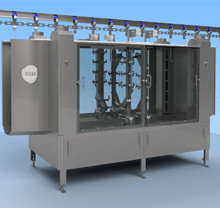

Head and Tongue Wash

Description:

- Moving arbors capture, contour, and follow each head and tongue for a targeted and effective wash

- Water is shut off in between washes, reducing water usage up to 60 percent

- Smaller system footprint allows more plant flexibility

- Electrostatic intervention technology available for a highly targeted and ultra-efficient cleaning, while reducing chemical usage by up to 95 percent

Beef, Pork & Lamb

Viscera Table Brush Assembly

Description:

- Use to wash, scrub and sterilize the moving top viscera table flights

- Custom-built to fit your viscera table

- Includes rinse and sterilizing sprays

- Available in electric or hydraulic drive

- Saves water

- Produces cleaner flights with no blood and tissue residue compared to high-pressure washing alone

Head and Tongue Wash Assembly

Description:

- Available as a fresh water wash, enhanced with antimicrobial solution, or hot water pasteurization

- Eliminates the inconsistency of hand washing

- Produces consistently cleaner heads and tongues while using less water

Head and Tongue Antimicrobial Spray Assembly

Description:

- Greatly reduces the chance of contamination in head and cheek meat by treating the heads and tongues with an antimicrobial solution immediately after washing and head inspection

- Can be floor mounted or suspended from an overhead structure

Offal Wash Assembly

Description:

- Produces consistently cleaner hearts, tails and livers while using less water

- Eliminates the inconsistency of hand washing

- Can be floor mounted or suspended from an overhead structure

Offal Antimicrobial Spray Assembly

Description:

- Greatly reduces the chance of contamination by treating offal with an antimicrobial solution immediately after viscera inspection and washing

- Can be floor mounted or suspended from an overhead structure

Carcass Wash

Description:

- Plants can use this system two ways: to remove loose tissue and bone dust and/or as an antimicrobial hurdle by infusing PAA or Lactic Acid

- Removing loose tissue, blood and bone dust is a critical step before hot water pasteurization to enhance the efficacy of the pasteurization process

Water Smart

Description:

- Patented technology

- Can cut water usage in carcass, head and tripe wash cabinets by 30% or more

- Plants using Water Smart see a return on investment within one year

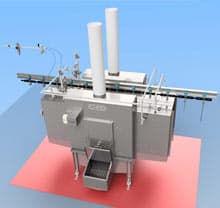

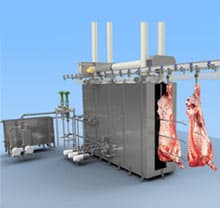

Hot Water Pasteurization System

Description:

- Patented recirculated hot water pasteurization system that can cut water usage in carcass, head and tripe wash cabinets by 30% or more

- Delivers 165° water to the surface of the carcass for a minimum of 10 seconds

- Provides one of the most effective antimicrobial hurdles on the harvest floor

- Applying hot water to the carcass surface after all dressing procedures greatly reduces the chances of pathogen contamination

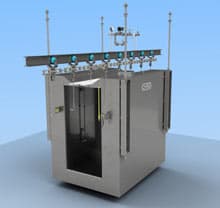

Antimicrobial Spray Cabinet

Description:

- Effectively delivers an antimicrobial to the entire carcass surface

- Spray is contained within the cabinet and exhausted out of the plant

- Can use with different types of antimicrobials such as Beefxide, Porkxide, Lactic Acid and PAA

Antimicrobial Spray Conveyor

Description:

- Integrates with existing processing equipment or conveyor system to apply antimicrobials

- Unlike some “one-size-fits-all” conveyors, our system is available in any width, length or height to match your specific needs

- Can use with different types of antimicrobials such as Beefxide, Porkxide, Lactic Acid and PAA

Automatic Mixing System

Description:

- Delivers the antimicrobial at the proper concentration, pressure and flow

- Automatic mixing systems available for manual mix, automated mix, high volume mix

Manual Mixing Station

Description:

- Delivers the antimicrobial at the proper concentration, temperature, pressure and flow

- Custom-built to your specifications

Chemical Mixing & Dispensing

Blend OnSite Solutions

Description:

- Chemical blending, dispensing and tracking system

- Dispenses the exact quantity, composition and concentration to your plant’s specifications

- Benefits reach every level of the plant- from chemical cost savings to tracking and reporting chemical usage and cost down to the department or individual level

- Download the Brochure

Sanitation Chemical Dispensing System

Description:

- Can be customized to fit your operation including the chemical quantities needed to ensure a thorough sanitation process

- Can deliver a single amount of multiple chemicals or differing amounts of one chemical

CIP, anti-foam and other chemical dispensing applications

Description:

- Fully customizable systems available to dispense chemicals to a CIP system, dispense antifoams or antimicrobials, or any other possible chemical application

- Whether you need to dispense ounces or gallons, we can create a solution to fit your needs

Liquik Trolley System

Description:

- Automatically monitors and delivers the proper chemical concentration in the trolley cleaning process, without the peaks and valleys that other systems experience

- Built-in safety features

- Manual override option can give the tank an extra boost for tough cleaning jobs

- Properly cleaned hooks mean no lost product

- PLC-based system provides simple operation

Liquik Tripe System

Description:

- Offers the consistency that a successful tripe cleaning operation needs

- Delivers the same amount of chemical to each load to ensure the yield and texture of your product

- Can work a stand-alone unit, requiring the operator to add the chemical with a push of a button or incorporated into the existing process automation that operates the full process

- Customizable to work with European-style tripe machines or multiples

DEMA 633 Blend Center Single Station Dispenser

Description:

- Unique modular design allows tool less connection of any number or systems

- Compact size makes for easy out of the way installation

- Easy to access for service without removing unit from the wall and water valve requires no tools to service

- Water inlet easily switches from left to right side

- Separate models for Action Gap or Air Gap back flow protection

DEMA 845/846 Industrial Laundry Master Dispenser

Description:

- Large stainless steel enclosure accommodates up to 6 pumps

- Two large pump options with volume of 40 ounces (1185ml) per minute and 50 ounces (1480ml) per minute

- 9 formula capability and separate USM formula remote

- On-board programming

Sanitation

Boot Scrubber

Description:

- Automatically washes and sanitizes the soles, tops and sides of boots

- Place at entry points to the plant to control cross-contamination between processing areas

Entry Way Sanitizer / Foamer

Description:

- Uniquely-designed foamer body generates more foam using less chemicals

- Fully programmable to dispense more product during peak travel times

Automatic Lug Wash

Description:

- Rinse, foam rinse and sanitize lugs

- Use hot or cold water

- Washes up to 6 lugs per minute

- Metered chemical and sanitizer application for consistency

- Payback in about 1 year

FOAM-iT Portable Foam Unit - 30 gallon

Description:

- Universal hinged back plate. Tool-free access to components

- Quick-change pump. Lift bracket to release pump

- Natural color tank helps you see product levels

- Hinged lid; available in 5 colors

- Front-facing drain

- In-line strainer protects pump from debris

- FOAM-iT item # FI-30N

- Also available in 5, 10, 15, 20, 25 and 50-gallon

FOAM-iT 15 Gallon Battery Foam Unit

Description:

- Draws from pre-mixed solution

- Battery-powered – no air lines or power cords to hold you back

- Use up to 2 hours from one charge

- Battery level indicator on back plate

- Use with low-foaming chemical products

- Natural color tank helps you see product levels

- Hinged lid, available in 5 colors

- Integrated hose wraps

- In-line strainer protects pump from debris

- FOAM-iT item # FI-BP-15N

FOAM-iT 10 Gallon Battery Foam Unit with Stainless Steel Ball Valve

Description:

- Draws from pre-mixed solution

- Battery operated

- Up to 45 minutes of use from one charge

- Stainless ball valve with foam fan tip

- Hinged back plate provides tool-free access to components

- Natural color tank helps you see product levels

- Hinged lid, available in 5 colors

- Integrated hose wraps

- Front-facing drain

- FOAM-iT item # FI-10N-B-SSBV

FOAM-iT Drain Foaming Attachment

Description:

- Foam travels through drains, providing 360° contact along pipe walls for maximum sanitation

- Stainless steel foam disc to cover drains up to 12 inches in diameter

- Rubber stopper to plug drains 3.5 to 5 inches in diameter

- Connects to compatible FOAM-iT units using included quick-connect fittings

- FOAM-iT item # DFA

FOAM-iT Trench Drain Foaming Attachment

Description:

- Foam travels through drains, providing 360° contact along pipe walls for maximum sanitation

- Stainless steel construction

- 7 inch round, flat brush designed for foaming trench drains

- Connects to compatible FOAM-iT units using included quick-connect fittings

- FOAM-iT item # DFA-TR7

Dosatron® 14 GPM Injector

Description:

- Install directly into water supply line; uses water pressure as its power source

- Chemical concentrate is proportionate to the volume of water, regardless of variations in main line flow and pressure

- Easy-to-read ratio selector

- GPM: 0.05 to 14 GPM (0.19 to 50 LPM)

- Pressure: 4.3 to 85 PSI

- Dosatron item # 14 GPM: D14MZ2

Water Temperature Controls

Emech® Digital Control Valves

Description:

- A highly optimized temperature control system

- High speed accuracy. Achieves more in less time

- Increases productivity while lowering utility and maintenance costs

- Superior valve performance allows you to run plans closer to constraints, thereby increasing production and yield

- Built to resist corrosion and minimize wear while providing maximum performance

- Patented valve disc system, swirl mixing action, high speed in valve sensing, with embedded PID control of a 100% duty cycle rated stepper motor digital actuator

Emech® Hot & Cold Water Mixer

Description:

- 3-port mixing valve uses ceramic shear action disc technology

- Provides tight shut-off, high pressure differential capability long-life integrity

- Fitted with electronic actuator and integrated temperature sensor

- High-performance stand-along closed-loop temperature control

- Temperature accuracy to +/- 1°F over a 32°F – 212°F control range

- Capable of blending from 0% to 100% of either inlet temperature

Emech® Steam/Water Mixer

Description:

- Instantaneous hot water generation

- Shear action disc design of the actuated valve mixes steam and water to precise hot water temperatures for critical cleaning and sanitation applications

- Fitted with electronic actuator and an integrated temperature sensor

- Fast, accurate and stable temperature control

- A constant supply of hot water at a precise temperature

- Single compact assembly simplifies installation

KOMAX Direct Injection Steam Heater

Description:

- Breakthrough in water heating and mixing technology, provides high energy efficiency with no maintenance cost

- Provides an unlimited supply of hot water – instantly

- Patented design features: Smooth operation, energy efficient, maintenance free, cost-effective

- Equip with an Emech actuator for precise temperature control

Hand Care

Hand Soap & Sanitizer Spray Pumps

HACCP 1-2 Knockout Pump Kit Item # DSP-0001

Description:

- Atomizing hand sanitizer spray pump kit for one gallon container

- Compatible with hard liter bottles

- Atomized spray saturates nails and cuticles

- Best Sanitizers item # KT10011

1 oz. Pump Dispenser Item # DSP-0004

Description:

- Removable cap and optional accessories

- Can be used with grit and pumice substances

- 38 mm cap fits standard gallon

- FDA compliant

- Tube Size: 10 3/4″

- Impact® Economy 1 oz. Plastic Dispensing Pump item #904

HACCP 1-2 Knockout Wrist-Activated Dispenser Item # DSP-0009

Description:

- Meets HACCP guidelines

- Wall mountable, stainless steel dispenser

- Accommodates one gallon bottles

- Includes KT10011 atomizing hand sanitizer pump kit for gallon bottle

- Best Sanitizers item # MD10006 – comes with KT10011 atomizing pump kit

- Best Sanitizers item # MD10003 – comes with KTFS1002 foaming pump kit

EZ-Step Wall-Mounted Foot-Activated Dispenser

Description:

- Meets HACCP guidelines

- Hands-free activation eliminates the increased possibility of cross-contamination

- Durable, stainless steel construction

- Best Sanitizers item # MD10105 – comes with KT10011 atomizing pump kit

- Best Sanitizers item # MD10110 – comes with KTFS1002 foaming pump kit

EZ-Step Portable Foot-Activated Dispenser

Description:

- For use with hand sanitizer spray only

- Meets HACCP guidelines

- Hands-free activation eliminates the increased possibility of cross-contamination

- Durable, stainless steel construction

- Best Sanitizers item # MD10012 – comes with KT10011 atomizing pump kit

Gallon Wall Bracket

Description:

- Meets HACCP guidelines

- Durable, stainless steel construction

- Best Sanitizers item # MD10200 – comes with KT10011 atomizing pump kit

- Best Sanitizers item # MD10201 – comes with KTFS1003 foaming pump kit

Touchless Hand Soap & Hand Sanitizer Dispenser

Description:

- 120VAC or battery-powered options

- Easy and quick change between soap and sanitizer

- Compatible with Birko hand soaps and sanitizers

- 1-gallon tank capacity

- Wide-angle spray nozzle (sanitizer only)

- Adjustable dispensing time

VersaClenz Manual Hand Hygiene Dispenser Item # DSP-0018

Description:

- Compatible with 17 different products

- ADA compliant

- Durable and splash resistant

- Best Sanitizers item # MD10030B

Prizefighter Dispensing System

Description:

- Automatic, watertight dispensers

- Durable, stainless steel construction

- Infrared sensors detects hands and dispenses a pre-measured amount of liquid soap or hand sanitizer spray

- Best Sanitizers item # AD10022 – Sanitizer spray

- Best Sanitizers item # ADS0002 – Liquid soap

Champion Multi-Line Dispensing System

Description:

- Automatic, watertight dispensers

- Durable, stainless steel construction

- Infrared sensors detect the presence of hands and dispense a pre-measured amount of liquid soap or hand sanitizer spray

- Best Sanitizers item # AD10008 – Sanitizer spray reservoir

- Best Sanitizers item # AD10009 – Liquid soap reservoir

- Best Sanitizers item # AD10019 – Sanitizer spray dispenser

- Best Sanitizers item # AD10019S – Liquid soap dispenser

Soap Foam Dispenser #9320 Item # DSP-0012

Description:

- Creates a thick and rich foam

- Foams regular lotion soaps with 1:3 soap to water dilution

- Greater skin area coverage with less soap dispensed

- More handwashings at less cost

- 800 ml capacity; dispenses .6 cc in liquid form

- Hidden locking mechanism

- Patented pump system

- Interline Brands item # 9320

Lotion Crank Dispenser #1300 Item # DSP-0014

Description:

- Made from high-impact, corrosion-resistant ABS plastic

- For 4-liter/1-gallon flat-top jug, approximately 1.4 cc per crank

- Contains built-in reservoir for ready supply of product

- Impact® Lotion Crank Soap Dispenser item # 1300

Refillable Liquid Dispenser

Description:

- Designed for Lotion Hand Soap (Big Red)

- 2 Liter Capacity Reservoir

- Robust High-quality ABS Plastic

Refillable Spray Dispenser

Description:

- Designed for Liquid Hand Sanitizer

(San-It E or Birko San III) - 2 Liter Capacity Reservoir

- Robust High-quality ABS Plastic